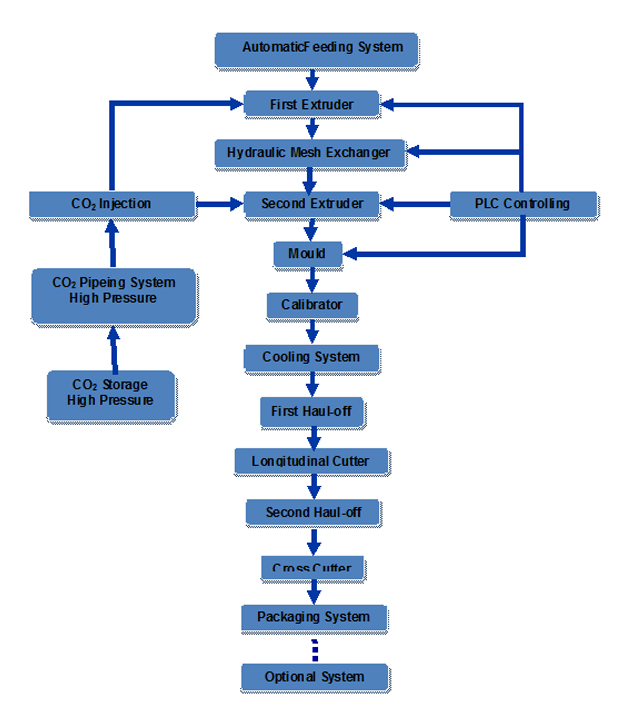

XPS Insulation Board Production Line with CO2 as foaming agent

WhatsApp: 13916133077

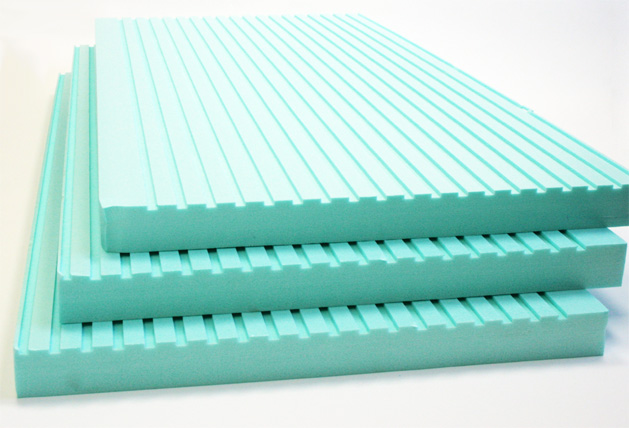

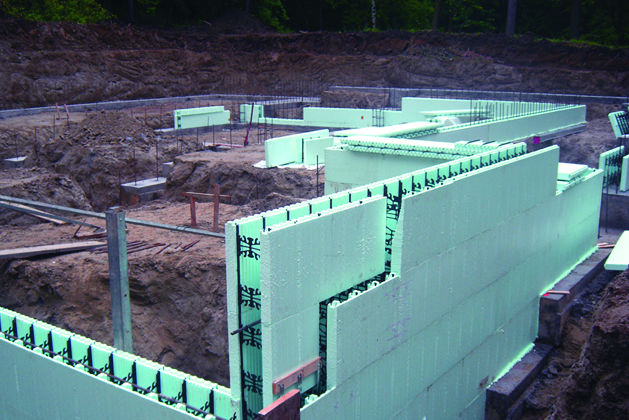

XPS Insulation Board, a kind of excellent insulation material, is a kind of Green Building Materials, which is foamed from a tendem extruding machinery by some kinds of special foaming agents, such as Freon, Butane, DME and/or CO2 with special technology.

Regarding to the characters of different foaming agents and different local environmental protection laws, the stipulation and application of foaming agents are different from different countries and different clients. Regarding to the characters of different foaming agents, the technology and equipment are different from each others.

HiSuccess International has developed top technology in XPS foaming machinery, applying CO2 as foaming agent, the cheapest foaming agent in XPS. The foaming result by CO2 is very good too.

The special features of CO2 as foaming agent:

1. As foaming agent of XPS board, CO2 is the cheapest one and used more and more by different countries. It’s a kind of environmentally friendly gas. It’s also totally non-flammable. It’s very safe in workshop and processing.

2. CO2 molecule is small and very stable, sometimes, CO2 is viewed as a kind of inert gas, its molecule is difficult to combine with GPPS molecule.

3. The condensing temperature of CO2 is about -70 ℃, so it's very difficult to keep CO2 in liquid within whole systems of XPS Production Line. And, keeping CO2 in liquid within whole systems of XPS Production Line, is frist important to get XPS board.

4. The systems of storage and injection for CO2 are all very high pressure systems so that to keep CO2 in liquid, from storage to injected into extruders to combine with XPS raw materials.

5. The XPS Insulation Board Production Line with CO2 as foaming agent is complex and complicated. It also needs a much longer and higher workshop.

6. The machinery with CO2 is more complicated and expensive. It means the total investment of machinery and plant will be much higher.

7. It’s needed a group of skillful engineers and operators for operation, maintenance and repairing.

XPS Insulation Board Production Line (CO2 as foaming agent)

|

Item |

HIM-XPS-500 |

HIM-XPS-600 |

HIM-XPS-700 |

||||

|

Extruding System |

Unit |

1st Extruder (Twin) |

2nd Extruder |

1st Extruder (Twin) |

2nd Extruder |

1st Extruder (Twin) |

2nd Extruder |

|

Screw Diameter |

mm |

Φ75 x 2 |

Φ160 |

Φ75 x 2 |

Φ170 |

Φ85 x 2 |

Φ200 |

|

L/D Radio |

L/D |

36:1 |

40:1 |

36:1 |

40:1 |

36:1 |

38:1 |

|

Motor Power |

Kw |

75 |

55 |

90 |

75 |

110 |

90 |

|

Capacity |

kg/h |

350 ~ 450 |

450 ~ 550 |

550 ~ 650 |

|||

|

Products Thickness |

mm |

20 ~ 100 |

20 ~ 100 |

40 ~ 120 |

|||

|

Total Power |

Kw |

280 |

350 |

440 |

|||

|

Workshop |

m |

100 x 20 x 10 |

120 x 20 x 10 |

120 x 20 x 10 |

|||

|

Item |

HIM-XPS-800 |

HIM-XPS-900 |

HIM-XPS-1000 |

||||

|

Extruding System |

Unit |

1st Extruder (Twin) |

2nd Extruder |

1st Extruder (Twin) |

2nd Extruder |

1st Extruder (Twin) |

2nd Extruder |

|

Screw Diameter |

mm |

Φ85 x 2 |

Φ250 |

Φ95X2 |

Φ250 |

Φ95X2 |

Φ300 |

|

L/D Radio |

L/D |

36:1 |

38:1 |

36:1 |

38:1 |

36:1 |

38:1 |

|

Motor Power |

Kw |

132 |

110 |

150 |

132 |

160 |

150 |

|

Capacity |

kg/h |

700 ~ 800 |

800 ~ 900 |

1000 ~ 1200 |

|||

|

Products Thickness |

mm |

50 ~ 150 |

50 ~ 150 |

50 ~ 150 |

|||

|

Total Power |

Kw |

480 |

550 |

600 |

|||

|

Workshop |

m |

130 x 20 x 10 |

140 x 20 x 10 |

150 x 20 x 10 |

|||

Copyright © HiSuccess International Machinery Limited Technical by SINGOO